Currently Empty: $0.00

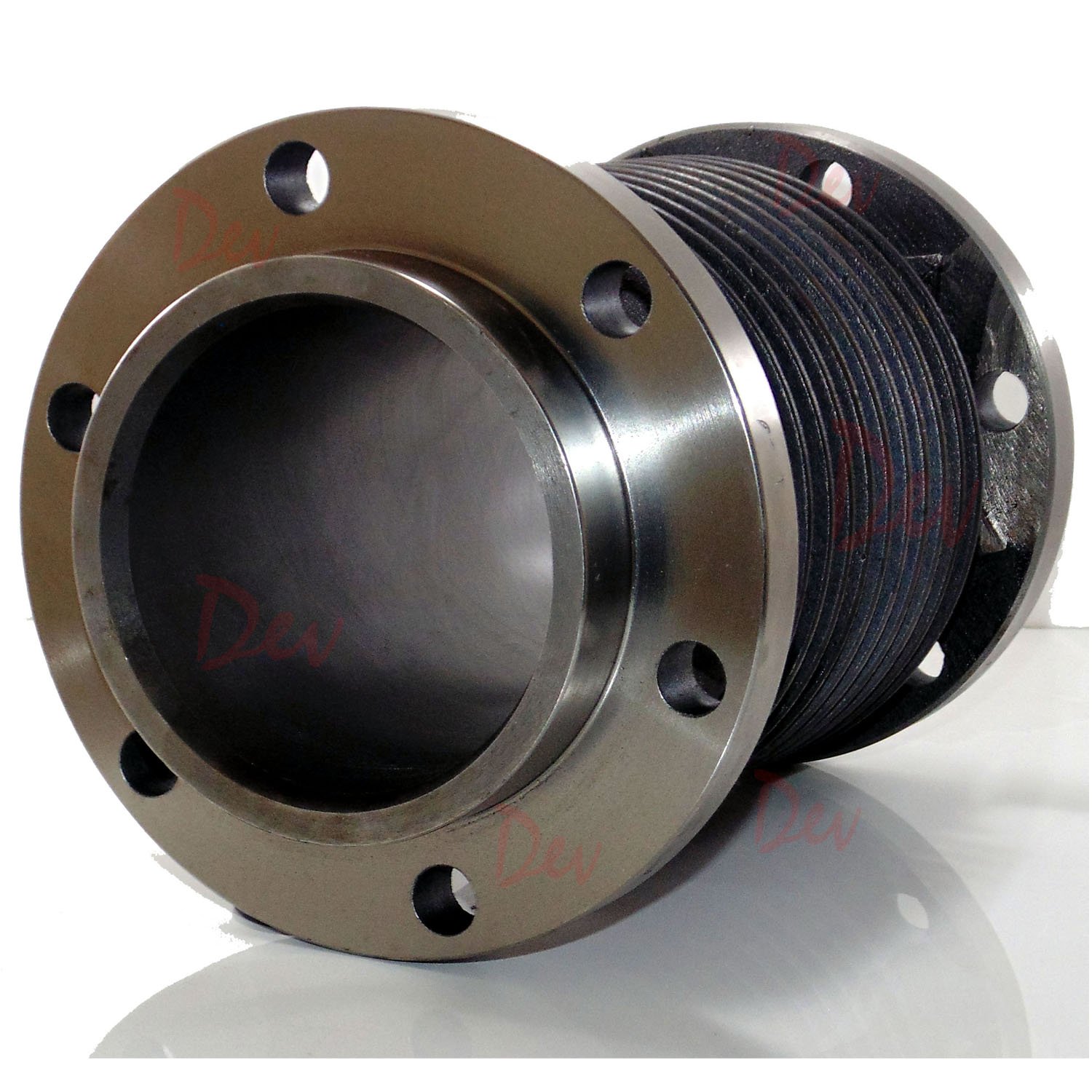

Air Cooled & Water Cooled Block

Cylinder Blocks are made of gray cast-iron, ought to have desired casting and machining qualities, viz. strength, toughness, hardness and wear resistance. Air Cooled Blocks are ideal for heat dispersion, these are widely used in compressors, generators, trucks, engines, and many more.

These are mainly of two types – Air Cooled Blocks and Wet Cooled Blocks.

In order to meet with industrial quality standards, we manufacture these Blocks from sand casting The inner bores are cross honed to provide maximum smoothness to the surface, that in turn reduces friction, when this inner bore is contacted with Piston Rings.

Quality:

- A very good plateau honing and cylindrical grinding that matches the geometrical parameters.

- Stringent material along with microstructure analysis of all the batches individually.

- Complete dimensional inspection of the finished components included in the process.

- Inspection of honing angle, structure and surface roughness at random.

- Tests of profiles, tensile strength and crack detection at regular intervals in a random way.

- Manufacturing experience for the past 25 years and an expertise with single roof manufacturing outlet.

- A very wide range and suitable for up to 1500 models for worldwide tractors, Diesel Engines, Stationary Engines and industrial engines.

- Can produce Blocks in bulk as well as small quantity in our patch production unit.Product Range:

- Phosphated Cylinder Block

- Chromed Cylinder Block

- Air Cooled Cylinder Block

- Water Cooled Cylinder Block

- Finned Cylinder Block

Material specification standards

India IS-FG 220 Europe GG20, GG25, GG30 American ASTM, A48 Micro Structure

Graphite type: “A” & “B” (“D” & “E” Random) Flake Size: 4-6 Microns Free Ferrite: Less Than 5% Matrix Lamellar Pearline Chemical Composition Minimum Maximum Carbon 2.90 3.50 Silicon 1.80 2.50 Manganese 0.6 1.00 Phosphorus 0.20 0.50 Phosphorus 0.00 0.12 Hardness (BHN) 210 to 280 Tensile (BHN) 210 to 280 n/mm2

Product Description

| MATERIAL |

Cast Iron ASTM Grade 40, GR40

|

| MFG PROCESS |

SAND CASTING

|

| FINISHING |

Honned, Polished, Grinning, Chromed, Nitrated

|

| FEATURES |

Anti Corrosive, Fine Finished, High Quality

|

| APPLICATION |

Compressors, Stationary Engines, Trucks, Tractors, Marine Engine, Earth Movers

|

| OUTSIDE DIA. |

50 mm to 160 MM Dia

|

| MAX LENGTH |

300 mm

|

| WEIGHTING |

1000 Kg

|

| Dimension | Range (in mm) |

|---|---|

| BORE DIAMETER | 50 TO 200 |

| OUTER DIAMETER | 60 TO 230 |

| TOTAL LENGTH | 110 TO 300 |