Currently Empty: $0.00

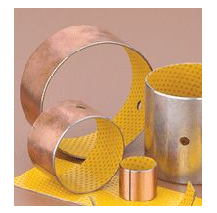

About Trimetalic Bush

TriMetal engine Bearings & Bushings have been the industry standard since the first patent on the cast, copper, lead composition decades ago. We manufacture & Export Plain, Thinwalled, Cut Type as well as Flange bushings in various metals & composition. We manufacture bushings for Railways (Locomotives), Compressors, Turbines, High Pressure Pumps, homogenizer, other rotating & reciprocating machinery. We manufacture these bushings Through Centrifugal Casting which enables us to manufacture Bushings in Large (Bulk) quantity as well as in small quantity.

Seizure Resistance – TriMetal Bearings & Bushings have as much as 20-40% better seizure resistance than competitors’ engine bearings.

Load Capacity – TriMetal Bearings & Bushings can withstand over 40-60% higher loads for extended periods compared to competitor bearings.

Embedability & Conformability – The overlay on a TriMetal™ bearing offers a superior surface for forgiveness, offering additional protection that can be extremely beneficial in an engine that is poorly maintained.

Durability – TriMetal Bearings & Bushings not only exceed light vehicle OE durability requirements, they also exceed heavy vehicle OE durability requirements.

Bearing design features a steel backing for support, a cast-copper lead alloy center for strength and a overlay of casted white metal/Lead for slipperiness, conformability and embedability. The intermediate cast-copper lead layer creates and interlocked columnar structure capable of withstanding much heavier pulsating loads than any other bearing design. They are more resistant to corrosion and out-perform traditional Bearings & Bushings by 10-20 % or more.

TIN Based Babbitt OVER LAY (WHITE METAL)

Tin based overlays contain copper (8-12%) as a hardening component.

The alloys are developed to replace toxic lead based overlays.

Tin based overlays possess excellent corrosion resistance and cavitation resistance. Overlay multilayer system of Sn alloy deposited on the bi-layer the overlay thickness due to varying content of copper (soft top layer and hard bottom layer of the overlay). Such multilayer Bearings & Bushings are capable to withstand alternating loads up to 11600-13000 psi (80-90 MPa).

Hardness of tin-copper overlays is 20-30 HV.

Product Description

| ITEM |

Trimetal Bush

|

| MATERIAL |

SAE 792, SAE 797, SAE 793, SAE 794, SAE 799

|

| OVER LAY COATING |

SAE12, SAE14, SAE15, BABBITT GRADE 90, BABBITT GRADE 84, WHITE METAL

|

| OUTER DIA |

10mm to 300mm

|

| LENGTH |

10mm – 150mm

|

| FEATURE |

PLAIN BUSH, THIN WALLED, CUT TYPE, FLANGED BUSH, THICK WALLED

|

| FINISHING |

Babbitt Visible, Fully Finish, Semi Finish, Plated Bush,

|

| Alloy Form | Lining Material | Metal Ref. | Brinell Hardness | Features And Applications |

|---|---|---|---|---|

| CAST BABBITT OVERLAY COATING / CASTING | LEAD BASED WHITE METAL | SAE-14 | 20 | THIS LEAD BASE BABBITT IS SOFT, EXCELLENT EMBED ABILITY FOR RELATIVE APPLICATIONS, MINIMUM LUBRICATION, GOOD RESISTANCE, LOW FATIGUE RESISTANCE AND HAS BEEN USED FOR MANY YEARS IN LOWER LOAD APPLICATION. |

| LEAD BASED WHITE METAL | SAE-15 | 18 | THIS LEAD BASE BABBITT HAS A GOOD BEARING PERFORMANCE, GOOD EMBED ABILITY AND HAS BEEN USED FOR MANY YEARS ON LOWER LOAD APPLICATION. | |

| TIN BASED WHITE METAL | SAE-12 | 32 | THIS TIN BASE BABBITT HAS GOOD SLIDING PROPERTIES, CONFORMABILITY AND HIGH TOUGHNESS; GOOD EMBED ABILITY SUITABLE FOR HIGH SLIDING VELOCITIES IN THE HYDRODYNAMIC RANGE, MEAN LOAD, IMPACT STRESS AT LOW FREQUENCY INSENSITIVE TO REVERSED BENDING STRESS. | |

| CAST COPPER LEAD | COPPER LEAD | SAE-793 | 80 | INCREASED HARDNESS AND WEAR RESISTANCE. INCREASING THE LEAD CONTENT IMPROVES THE TOLERANCE OF POOR ALIGNMENT AND INTERMITTENT LUBRICATION |

| COPPER LEAD | SAE-792 | 85 | THIS MATERIAL IS BEST SUITED FOR BUSHINGS AND WASHERS SUBJECTED TO HIGH IMPACT AND VIBRATORY LOADS. IN MOST CASES, IT OPERATES BEST WITH HARDENED SHAFT. | |

| COPPER LEAD | SAE-49 | 60 | HIGH FATIGUE STRENGTH, NORMALLY PLATED WITH AN OVERLAY WHEN USED IN BEARING APPLICATION AND IN THIS FORM MAY BE OPERATED WITH HARD OR SOFT SHAFTS SUSCEPTIBLE TO CORROSION BY DEGRADED OIL WHEN NOT OVERLAY PLATED | |

| COPPER LEAD | SAE-794 | 62 | HIGH FATIGUE STRENGTH AND SHOCK RESISTANCE, SUITABLE FOR HIGH SPEED SHAFTS, OSCILLATING OR ROTATING MOTION HARD SHAFT DESIRABLE, NORMALLY OVERLAY PLATED WHEN USED IN BEARING APPLICATION. | |

| SINTERED COPPER LEAD | COPPER LEAD | SAE-792 | 110 | THIS MATERIAL IS BEST SUITED FOR BUSHINGS AND WASHERS SUBJECTED TO HIGH IMPACT AND VIBRATORY LOADS. IN MOST CASES, IT OPERATES BEST WITH A HARDENED SHAFT. |

| COPPER LEAD | SAE-49 | 55 | THIS IS A BEARING MATERIAL DESIGNED EXCLUSIVELY FOR HIGH LOAD. THE MATERIAL IS PLATED WITH A UNIQUE TRI METAL OVERLAY AND NICKEL DAM. | |

| COPPER LEAD | SAE-794 | 50 | THIS MATERIAL IS EMPLOYED FOR BUSHINGS AND THRUST WASHERS APPLICATIONS SUBJECTED TO INTERMEDIATE IMPACTS AND VIBRATORY LOADS. IT HAS CERTAIN DEGREE OF EMBED ABILITY AND IT IS SUITABLE FOR HIGHER SPEED AND LOAD. | |

| OVERLAY PLATING | LEAD TIN | SAE-191 | 12 | - |

| LEAD TIN COPPER | SAE-192 | 14 | - |